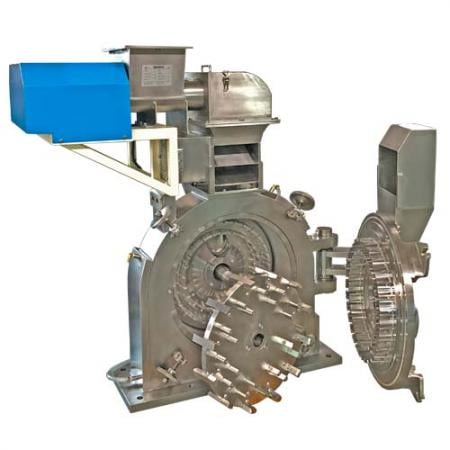

Pin Mill

Pin Mill is suitable to grind crystal and brittle materials. The output fineness can be changed by replacement of the filtering-screen and adjustment of the rotor speed. With a wild range of applications to a variety of products, and the features of optional grind disc replacement for proper materials. Especially, this machine is easy to clean (water rinse) and do maintenance.

PM Series

- Easy Operation

- Washable

- Applicable for Various Materials

- Fineness:40~100 mesh (Depend on different materials.)

- Capacity:20kg ~ 2000kg/hr

- Operate as a single machine or within a turnkey system

Advantage

- Processes a wide range of raw materials. Durable, low-waste design.

- Easy to operate, saves time & power, highly efficient.

- Durable components are easy to replace & clean.

- Fineness: 40 ~ 100Mesh. (data is for reference only & may vary according to raw material)

- Features

Ideal for pulverizing any materials (except highly oily or sticky ones). Due to the variety and interchangeability of internal components, this equipment has wide production adaptability, ranging from granular material to super-fine particles. Turnkey system is designed to prevent contamination of materials, increase efficiency, lower manpower requirements and maintain material quality.

PRINCIPLE

Raw material is fed into the grinding chamber from the feeding hopper.

The first grinding is a shearing force created by the cutting impact of the inner rotor and stator.

After filtrating, any remaining coarser powder will be ground in the third grinding until it passes through the screen mesh.

The finished product is discharged from the rotary valve.

►PM-1 Compact Milling System ►PM-3-C For Cosmetics ►PM-3 For Foodstuffs

Stud Type Rotor Stud Type Stator Screen Ring Application

Brittle materials: achieves exceptionally high

grinding fineness at low specific energy consumption.Pin Type Rotor Pin Type Stator Screen Ring Application

Grains, Beans, Seasonings, etc.

(e.g. Rice, Green Beans, Sugar, Salt).Knife Type Rotor Knife Type Liners Screen Ring Application

High Fiber & Heat Sensitive Raw Materials.

(e.g. Chinese Herbs).- Specifications

Application Model Power

(HP)RPM Capacity

(KG/HR)Dimensions

(L*W*H mm)Fineness

(Mesh)GMP(Standard) PM-3-A 5~7 1/2 5000~7500 100~200 1000*600*1400 100~250 GMP(Standard) PM-4-A 7 1/2~10 4500~6500 200~300 1100*700*1500 100~250 Foodstuff & Chemical Grade PM-1 2 3500 20~50 500*560*1300 20~150 Foodstuff & Chemical Grade PM-3 5~7 1/2 3500 80~250 1100*700*1550 20~150 Foodstuff & Chemical Grade PM-4 7 1/2~10 3000 100~300 1200*800*1750 20~150 Foodstuff & Chemical Grade PM-5 15~20 2900 150~500 1500*900*2200 20~150 Foodstuff & Chemical Grade PM-6 30~40 2800 300~900 1700*1000*2400 20~150 Foodstuff & Chemical Grade PM-7 50~60 2700 500~2000 1900*1300*2900 20~150 Cosmetics Grade PM-3-C 7 1/2 3500 200~300 1000*860*1200 100~200 Height from floor to outlet: 450 mm Capacity:

According to different characteristics of materials and equipment, the data would be changed.- File Download

- Application

01. Grains, Beans, Foodstuff & Bakery Powder

02. Sugar, Seasoning

03. Spices

04. Biotech/Pharmaceutical, Chinese herbs & Healthy Food

05. Plastic, Chemical, Mineral

06. Environmental Recycling Material

07. Applied Material

- Tunkey System

Pin Mill Grinding

Changeable rotors and filter screens, our pin mill able to handle different materials and create...

Treatment

- Grinder

Material Properties

- Non-Oily

Fineness

- 40mesh ~ 100mesh

Capacity

- 20kg ~ 2000kg/hr

Production Methods

- Single Machine

Looking for GMP-Compliant Grinding Equipment for Pharmaceutical Ingredients?

Mill Powder Tech's PM-3-A and PM-4-A models are specifically designed for pharmaceutical applications with full GMP compliance. The completely washable construction enables thorough cleaning between batches, preventing cross-contamination of active pharmaceutical ingredients. Process antibiotics, herbal extracts, and drug formulations with fineness up to 250 mesh at capacities of 100-300kg/hr. Our knife-type rotor option handles heat-sensitive compounds without degradation. Request detailed specifications and validation documentation to ensure compliance with your pharmaceutical manufacturing standards.

Designed with operational efficiency and hygiene standards in mind, our pin mill grinding system features a fully washable construction that simplifies cleaning and maintenance procedures, making it ideal for GMP-compliant pharmaceutical applications and food-grade processing requirements. The equipment's durable, low-waste design processes a wide range of raw materials including spices (pepper, turmeric, cinnamon), sugars, salts, coffee beans, grains, pharmaceutical ingredients, Chinese herbal medicines, chemical compounds, and plastic additives - excluding only highly oily or sticky materials. Available in foodstuff grade, chemical grade, GMP standard, and cosmetics grade configurations, the PM Series can operate as a standalone unit or integrate seamlessly into complete turnkey powder processing systems. This flexibility, combined with easy component replacement, low power consumption, and high efficiency operation, makes Mill Powder Tech's Pin Mill the preferred choice for manufacturers seeking reliable, versatile grinding solutions that maintain product quality while maximizing productivity.