Bio Technology Materials

Application Type

- 04. Biotech/Pharmaceutical, Chinese herbs & Healthy Food

- Products

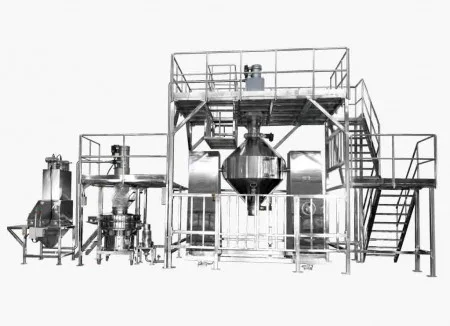

Rotary Cone Mixer

Outer barrel and inner arm run in different speed and reserve direction. High mixing speed, high uniformity and easy cleaning.

DetailsVibro Separator & Vibro Filter

By shaking force to filter the request particle size, it can process the most 4 sizes of particle with 4 layers of screen. Quick replacement of the sieving...

Details