Color Dyes

Application Type

- 05. Plastic, Chemical, Mineral

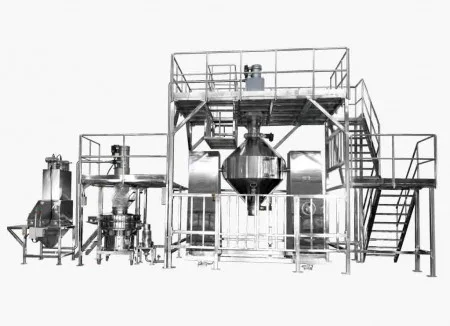

- Tunkey System

- Products

Turbo Mill

Turbo Mill is different from other kinds of grinders. Raw materials will be ground via the force of cutting, impact, innumerable high speed vortex and high...

DetailsImpact Classified Mill

This ICM is made up of a special grind disc and a classifier. According to the characteristic of the materials proffer the best solution to meet the need...

DetailsRibbon Mixer

Ribbon Mixer is designed with Twin mixing Ribbon. During mixing, twin ribbon can mix powder in convective direction, inner and outer, up and down to even...

DetailsRotary Cone Mixer

Outer barrel and inner arm run in different speed and reserve direction. High mixing speed, high uniformity and easy cleaning.

DetailsVibro Separator & Vibro Filter

By shaking force to filter the request particle size, it can process the most 4 sizes of particle with 4 layers of screen. Quick replacement of the sieving...

Details