Mixing Convey Packing

Powder mixing total solutions

Need a Complete Mixing-to-Packaging Solution That Handles Multiple Product Formulations?

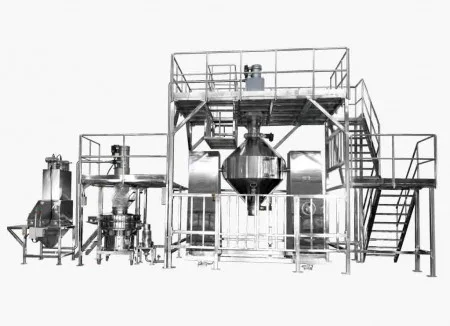

Mill Powder Tech's turnkey mixing conveying packing systems are engineered for versatile multi-product operations. Our systems seamlessly handle diverse materials from fine spices and seasonings to chemical detergents and bakery powders, with quick changeover capabilities and precision batch control. Each system includes integrated sieving to remove lumps, ribbon mixing for homogeneous blending, pneumatic conveying for dust-free transport, and automated packing with accurate dosing. Request a consultation to explore how our 70 years of expertise can optimize your production efficiency and product consistency.

Backed by 70 years of powder technology expertise, our mixing conveying packing systems feature robust construction, sanitary design standards, and flexible configurations to accommodate diverse production requirements. Each system integrates multiple processing stages including vacuum suction feeding, precision sieving, homogeneous mixing, controlled conveying, accurate weighing, and automated filling operations. Our turnkey solutions minimize material waste, prevent cross-contamination, and optimize floor space utilization while meeting strict food safety and industrial standards. From small-scale bakery operations to large-scale chemical production facilities, Mill Powder Tech delivers reliable, high-performance systems that maximize productivity and ensure long-term operational success.