Pill (Lozenges Solution Ingot)

Application Type

- 04. Biotech/Pharmaceutical, Chinese herbs & Healthy Food

- Tunkey System

- Products

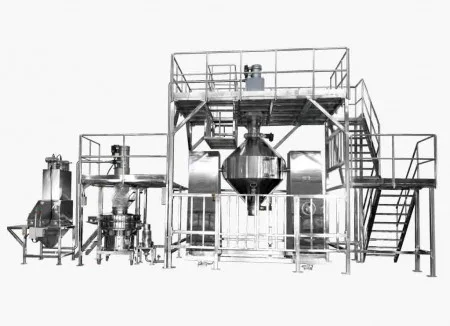

Rotary Cone Mixer

Outer barrel and inner arm run in different speed and reserve direction. High mixing speed, high uniformity and easy cleaning.

Details