Rotary Cone Mixer

Outer barrel and inner arm run in different speed and reserve direction. High mixing speed, high uniformity and easy cleaning.

RC Series

- The outer barrel and inner blades are being controlled by separate motors which enhance mixing strength, and having different strength, and having different rotating homogeneous mixing.

- Features

It is designed to be tilted freely at angle 0° ~360° degrees. In addition to manual opening inlet and outlet, it can be customized with pneumatic control.

Fully stainless steel polished finishng meeting GMP requirement without dead angle.Oil/Liquid spreading device is optional.

Water proof control box,digital timer,overload protector device,ampere and meter are included.

The automatic stopping device can be set within the range of 0-60 minutes for automatic stopping.

Easy to operate,easy to wash,clean and move. It is very suitable for GMP food and pharmaceutical factories.

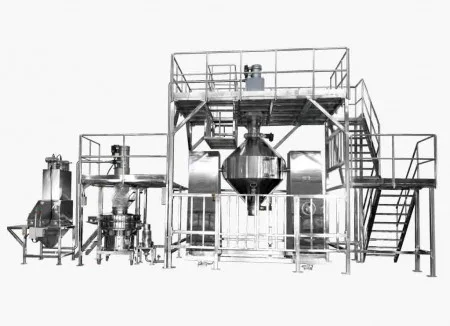

►Rotary Cone Mixer-RC1000

(Capacity:2400KG/Batch)

Inner Blade Inner Oil Spraying Device Inner(Fixed Plate)

- Specifications

Model Volume

(KG/L)Motor

(HP)Dimension

(L*W*H mm)Shaft Outer-Barrel RC-50 50/120 1 2 1800*750*1560 RC-100 100/260 2 3 1900*880*1700 RC-200 200/500 2 3 2300*1200*1900 RC-300 300/700 3 5 2430*1300*2100 RC-500 500/1200 3 7 1/2 2800*1450*2400 RC-1000 1000/2400 5 15 3500*1700*2700 RC-2000 2000/5000 15 25 4100*2000*3400 RC-3000 3000/7000 20 40 4500*2500*4600 Capacity:

According to different characteristics of materials and equipment, the data would be changed.- File Download

- Application

01. Grains, Beans, Foodstuff & Bakery Powder

02. Sugar, Seasoning

04. Biotech/Pharmaceutical, Chinese herbs & Healthy Food

05. Plastic, Chemical, Mineral

- Tunkey System

Treatment

- Mixer

Material Properties

- Oily

- Non-Oily

Capacity

- 10kg ~ 1500kg/Per Lot

Production Methods

- Single Machine

Need GMP-Certified Mixing Equipment That Eliminates Cross-Contamination Risks?

Our Rotary Cone Mixer RC Series features fully polished stainless steel construction with zero dead angles, meeting stringent GMP requirements for pharmaceutical manufacturing. The design ensures complete product discharge and effortless validation cleaning between batches. Contact us today to discuss your pharmaceutical powder mixing requirements and receive a customized solution that meets FDA and international regulatory standards.

The RC Series distinguishes itself through versatile operational capabilities including 360-degree free tilting, optional pneumatic inlet/outlet controls, and an integrated oil/liquid spreading device for processing formulations requiring liquid addition. Each unit comes equipped with a waterproof control panel, digital timer with 0-60 minute auto-stop functionality, overload protection, and comprehensive monitoring instruments. The cone mixer's ergonomic design facilitates easy operation, thorough washing, and mobility—making it the ideal solution for GMP-certified food processing facilities, pharmaceutical manufacturing plants, and chemical production operations. From coffee powder and bakery mixes to pharmaceutical compounds and chemical additives, our rotary cone mixer delivers consistent, reliable performance across diverse powder blending applications, backed by Mill Powder Tech's 70 years of manufacturing excellence.