Struggling with Inconsistent Powder Blending in Bakery Ingredients?

Our Ribbon Mixer with twin mixing ribbons delivers superior uniformity for bakery powder applications where consistency is critical. The convective mixing action moves powder in multiple directions—inner, outer, up, and down—ensuring thorough blending of flour, sugar, leavening agents, and other ingredients. Bakery ingredient suppliers trust our ribbon mixing technology to achieve CV values below 5% in minutes, not hours. Whether you're blending cake mixes, bread improvers, or specialty baking powders, our customizable ribbon mixers handle batch sizes from 50kg to 3000kg. Request a free mixing analysis to see how we can improve your product consistency and reduce batch rejection rates.

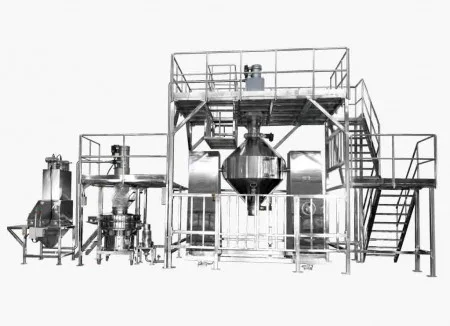

Our product lineup includes the Ribbon Mixer with twin mixing ribbons for convective powder blending, Rotary Cone Mixer with dual-speed operation for high uniformity, and complete Foodstuff Crushing Grinding Mixing Systems that integrate multiple processing stages. We offer specialized solutions such as Vacuum Suction-Sieving-Mixing Systems for contamination-free processing and Grain Mixing & Transporting Packing Systems for end-to-end automation. Each system is customizable to match specific production requirements, particle size specifications, and throughput demands. Our engineering team works closely with grain processors, bakery ingredient suppliers, food additives manufacturers, and starch producers to design optimal solutions that maximize productivity, ensure consistent quality, and reduce operational costs. From standalone equipment to fully integrated production lines, Mill Powder Tech delivers reliable, durable machinery backed by outstanding technical support and prompt worldwide delivery.