Additive

Application Type

- 05. Plastic, Chemical, Mineral

- Products

Intermediate Bulk Container

Changeable bins can be either storage or mixing. Efficiently reduce cross-contamination, great mixing performance.

DetailsRibbon Mixer

Ribbon Mixer is designed with Twin mixing Ribbon. During mixing, twin ribbon can mix powder in convective direction, inner and outer, up and down to even...

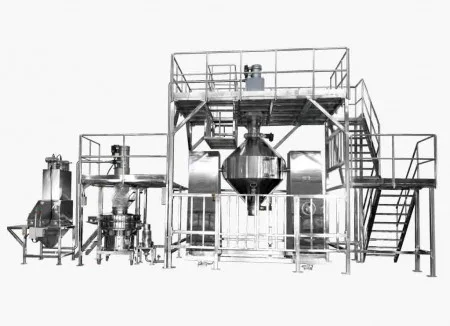

DetailsRotary Cone Mixer

Outer barrel and inner arm run in different speed and reserve direction. High mixing speed, high uniformity and easy cleaning.

Details