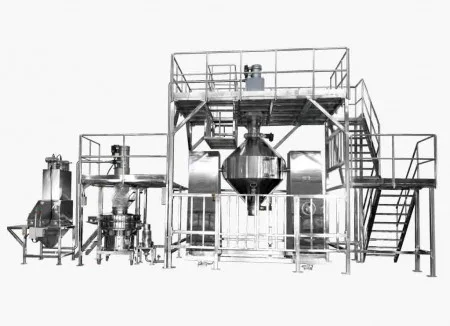

خلاط مخروط دوار

يعمل البرميل الخارجي والذراع الداخلية بسرعات مختلفة وفي اتجاهات معاكسة. سرعة خلط عالية، تجانس عالي وسهولة في التنظيف.

سلسلة RC

- يتم التحكم في البرميل الخارجي والشفرات الداخلية بواسطة محركات منفصلة تعزز من قوة الخلط، ولها قوة مختلفة، ولها خلط متجانس دوار مختلف.

- الميزات

تم تصميمه ليكون مائلًا بحرية بزاوية 0° ~360° درجة. بالإضافة إلى فتحة الدخول والخروج اليدوية، يمكن تخصيصه مع التحكم الهوائي.

تشطيب مصقول من الفولاذ المقاوم للصدأ بالكامل يلبي متطلبات GMP بدون زوايا ميتة. جهاز توزيع الزيت/السائل اختياري.

صندوق تحكم مقاوم للماء، مؤقت رقمي، جهاز حماية من الحمل الزائد، أمبير ومقياس مشمول.

يمكن ضبط جهاز التوقف التلقائي ضمن نطاق 0-60 دقيقة للتوقف التلقائي.

سهل التشغيل، سهل الغسل، التنظيف والتحريك. إنه مناسب جدًا لمصانع الأغذية والأدوية وفقًا لمعايير GMP.

►خلاط مخروط دوار-RC1000

(السعة:2400 كجم/دفعة)

الشفرات الداخلية جهاز رش الزيت الداخلي الداخلية (اللوحة الثابتة)

- المواصفات

نموذج الحجم

(كجم/لتر)محرك

(حصان)الأبعاد

(طول*عرض*ارتفاع مم)عمود البرميل الخارجي RC-50 50/120 1 2 1800*750*1560 RC-100 100/260 2 3 1900*880*1700 RC-200 200/500 2 3 2300*1200*1900 RC-300 300/700 3 5 2430*1300*2100 RC-500 500/1200 3 7 1/2 2800*1450*2400 RC-1000 1000/2400 5 15 3500*1700*2700 RC-2000 2000/5000 15 25 4100*2000*3400 RC-3000 3000/7000 20 40 4500*2500*4600 السعة:

وفقًا لخصائص المواد والمعدات المختلفة، ستتغير البيانات.- تحميل الملف

- تطبيق

01. الحبوب، الفاصوليا، المواد الغذائية ومسحوق المخابز

02. السكر، التوابل

04. التكنولوجيا الحيوية/الصيدلانية، الأعشاب الصينية والطعام الصحي

05. البلاستيك، الكيميائيات، المعادن

- نظام تسليم مفتاح

المعالجة

- خلاط

خصائص المواد

- دهني

- غير دهني

السعة

- 10 كجم ~ 1500 كجم/ لكل دفعة

طرق الإنتاج

- آلة واحدة

هل تحتاج إلى معدات خلط معتمدة من GMP تقضي على مخاطر التلوث المتبادل؟

تتميز خلاط المخروط الدوار من سلسلة RC بإنشاء مصنوع من الفولاذ المقاوم للصدأ المصقول بالكامل مع زوايا ميتة صفرية، مما يلبي متطلبات GMP الصارمة لصناعة الأدوية. يضمن التصميم تفريغ المنتج بالكامل وتنظيف سهل للتحقق بين الدفعات. اتصل بنا اليوم لمناقشة متطلبات خلط المساحيق الدوائية الخاصة بك واحصل على حل مخصص يلبي معايير FDA والمعايير التنظيمية الدولية.

تتميز سلسلة RC بقدرات تشغيلية متعددة الاستخدامات تشمل الميل الحر بزاوية 360 درجة، والتحكمات الهوائية الاختيارية للدخول/الخروج، وجهاز متكامل لنشر الزيت/السائل لمعالجة التركيبات التي تتطلب إضافة سائل. تأتي كل وحدة مزودة بلوحة تحكم مقاومة للماء، مؤقت رقمي مع وظيفة إيقاف تلقائي من 0 إلى 60 دقيقة، حماية من الحمل الزائد، وأدوات مراقبة شاملة. يُسهل التصميم المريح لخلاط المخاريط التشغيل السهل، والغسل الشامل، والتنقل - مما يجعله الحل المثالي لمرافق معالجة الطعام المعتمدة من GMP، ومصانع تصنيع الأدوية، وعمليات إنتاج المواد الكيميائية. من مسحوق القهوة وخلطات المخابز إلى المركبات الصيدلانية والإضافات الكيميائية، يوفر خلاط المخروط الدوار لدينا أداءً متسقًا وموثوقًا عبر تطبيقات خلط المساحيق المتنوعة، مدعومًا بـ Mill Powder Tech التي تتمتع بخبرة تصنيع تمتد لـ 70 عامًا.