迴轉圓錐混合機

迴轉圓錐混合機內部採用內外迴轉攪拌、且混合桶與混合內葉採相反方向360度混合,混合速度快、均勻度高、易清洗。

RC 系列

- 採用內外迴轉攪拌、且混合桶與混合內葉採相反方向360°混合,混合速度快、均勻度高、易清洗。

- 產品內容

混合桶可任意傾斜角度、出料採用手動碟閥或氣動碟閥便於出料及清潔之需要。

混合桶完全無死角、易清洗完全符合GMP要求,可因應原料需要外加噴油裝置。

隱藏式電控箱,防水性佳並設有自動及手動定時裝置、過載保護開關、安全保護裝置,安全性高、操作容易。

設有自動定時裝置,可設定0~60分鐘自動停止。

操作簡單,容易清洗,適合GMP食品、藥廠使用。

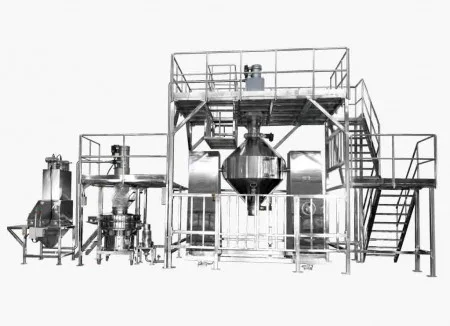

►迴轉圓錐式混合機-RC1000

(容量:2400KG/處理量)

示意圖

內部(葉片式) 內部(葉片式)加裝噴油裝置 內部(導流板式)

- 產品規格

型式 容量

(公斤/公升)馬力

(HP)機械尺寸

(長*寬*高 mm)主軸 外桶 RC-50 50/120 1 2 1800*750*1560 RC-100 100/260 2 3 1900*880*1700 RC-200 200/500 2 3 2300*1200*1900 RC-300 300/700 3 5 2430*1300*2100 RC-500 500/1200 3 7 1/2 2800*1450*2400 RC-1000 1000/2400 5 15 3500*1700*2700 RC-2000 2000/5000 15 25 4100*2000*3400 RC-3000 3000/7000 20 40 4500*2500*4600 產量:

視設備規格與原物料之特性不同而有所改變。- 附件下載

- 原料應用

01. 五穀豆類及食品烘焙原料

02. 糖、調味料

04. 生技製藥、中藥材、健康食品

05. 塑料、化工、礦石

- 整廠設備

處理方式

- 混合

原料特性

- 油性

- 非油性

產量

- 10kg~1500kg/批次

生產方式

- 單機

- 整廠

凌廣粉体科技 迴轉圓錐混合機服務簡介

凌廣工業股份有限公司是台灣一家擁有超過70年經驗的專業迴轉圓錐混合機生產製造服務商。 我們成立於西元1940年, 在粉碎機與磨粉機等粉碎混合機械市場領域上, 凌廣粉体科技提供專業高品質的迴轉圓錐混合機製造服務, 凌廣粉体科技 總是可以達成客戶各種品質要求。

凌廣粉体科技邀請您立即瀏覽我們各項產品服務並立即聯絡我們。