Biotech/Pharmaceutical

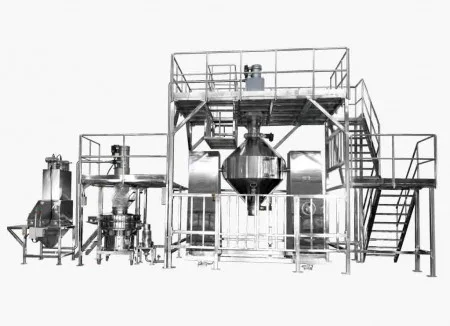

Biotech(Herbs) Grinding System

- Application

- Related Product

Rotary Cone Mixer

Outer barrel and inner arm run in different speed and reserve direction. High mixing speed, high uniformity and easy cleaning.

DetailsPowder Grinder

This special design of centrifugal grinding roller and groove will grind the raw material to appropriate fineness and then final powder will be discharged...

Details