Materiales de Biotecnología

Tipo de Aplicación

- 04. Biotecnología/Farmacéutica, hierbas chinas y comida saludable

- Productos

Molino de Pin

El molino Pin es adecuado para moler materiales cristalinos y quebradizos. La finura de salida se puede cambiar mediante el reemplazo de la malla filtrante...

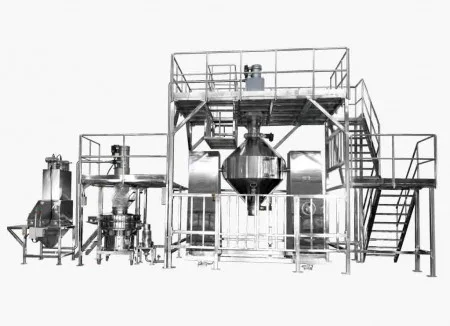

DetallesMezclador de Cono Rotatorio

El barril exterior y el brazo interno funcionan a diferentes velocidades y en direcciones opuestas. Alta velocidad de mezcla, alta uniformidad y fácil...

DetallesSeparador Vibro y Filtro Vibro

Al sacudir para filtrar el tamaño de partícula requerido, puede procesar hasta 4 tamaños de partícula con 4 capas de pantalla. Reemplazo rápido de la pantalla...

Detalles